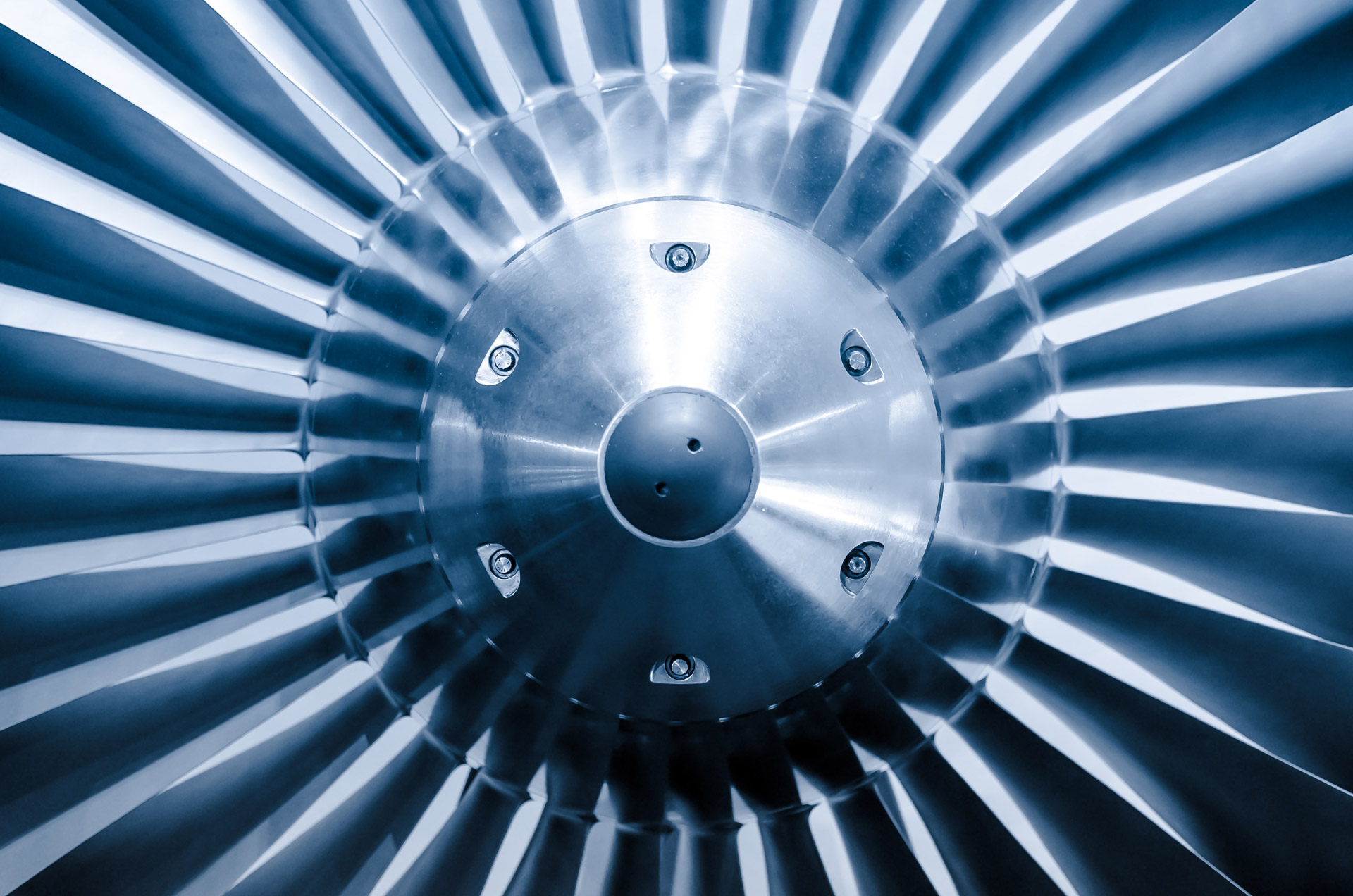

Aerospace and Defense (ASD)

#mk-page-title-box-68630e473feb6 { height: 300px; background-color: ; text-align: center; } #mk-page-title-box-68630e473feb6 .mk-page-title-box-title { font-size: 50px; line-height: 50px; font-weight: bold; color: #ffffff; padding-bottom: 10px; margin-bottom: 10px; letter-spacing: 1px; } #mk-page-title-box-68630e473feb6 .mk-page-title-box-title--underline:after { background: #ffffff;} #mk-page-title-box-68630e473feb6 .mk-page-title-box-subtitle { font-size: 18px; line-size: 18px; font-weight: normal; color: #ffffff;} #mk-page-title-box-68630e473feb6 .mk-effect-bg-layer { background-image: url("http://www.lubodry.fr/wp-content/uploads/2015/11/shutterstock_229816288_sd.jpg"); background-position:center top; }

LUBODRY® PRODUCTIONS is the European leader in dry lubricants impingement processes for the aeronautics, space and defense industries.

We offer our clients tailor-made, controlled and reproductible solutions:

- For small or large-series production

- For small or large workpieces : diameter up to 36 inches and length up to 33 ft

- For workpieces of other dimensions and large-series productions, it is possible to co-develop a specific industrial equipment according to our clients’ requirements.

Our expertise in the field of tribology under extreme environments brings industrial designers and R&D centers what makes a successful project:

- A technically feasible and effective lubricznt solution

- Permanent and maintenance-free

- Environment-friendly

- Available for small- and large-series production

- Compliant with the industry’s highest standards (EN 9100)

- Reactive, including AOG / emergency services

- Cost-effective

- Which improves the competitiveness of your workpieces and equipments

For over 20 years, LUBODRY PRODUCTIONS has been investing in people, equipment and innovation to provide tailored-made lubricant solutions to the requirements of the Aerospace and Defense (ASD) industry :

- Give life to the most complex projects in extreme conditions : anti-friction, anti-seizure, anti-wear, anti-adhesion through a range of dry lubricant processes, selected according to their own physical and functional characteristics

- Treat then ship back your workpieces in emergency, following the AOG policy (Aircraft On Ground)

- And ensure top quality of lubricant coatings without modifying the original dimensions of your workpieces and always meet the deadlines, including in the context AOG orders

We offer our clients more than just a coating application:

- We select and test the best lubricant process depending on the expected performance and the operating environment

- We advise your Design & Development departments in order to ensure perfect match between the workpieces and surface treatment

- We assist you in developing your technical requirements : key feature specifications, control plan, etc.

- Our operational organization is focused on process control and quality

- We master a broad range of lubricant solutions, including Graphite, Molybdenum Disulfide (MoS2) or Tungsten Disulfide (WS2) based impingement processes : Our lubricant processes do not create extra thickness on your workpieces, thus do not modify their original dimensions